DIY Dry box — Part 3

So now we have a dry box. But the usage is a bit limited. The spool has to be taken out of the box each time we want to use it.

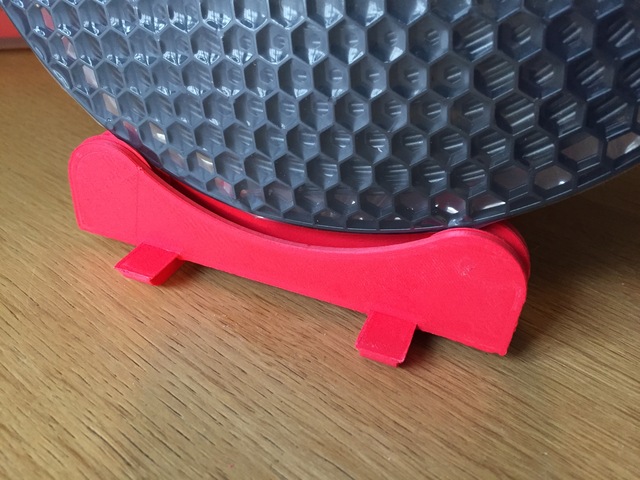

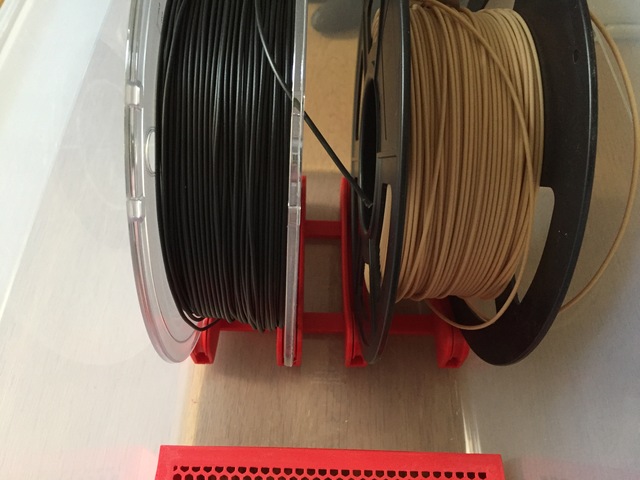

The idea now is to print some supports that will allow the spools to roll. I got inspired by The Ultimate Spool Holder, to design something similar that could work for big spools (1 or 2 kg) but also for smaller ones (250 g). I also included notches to put the spool holders on rails that are as long as the box is wide.

The volume my printer can print is not big enough to design a piece as big as the box, so I have to take this more modular approach. Also, if it doesn’t work, I can still use it without the box.

For this print I also need some skateboard/rollerblade ball bearings. I have cheap and expensive ones. It works better with the expensive ones, but the cheap ones are good enough.

The main issue I encountered was that spools were not stable. The movements when putting the boxes in the IKEA shelf were enough to make the spools fall out of the holders.

The solution was to print some spacers that would keep the space between holders but also prevent the spools to slide forward/backward in the box.

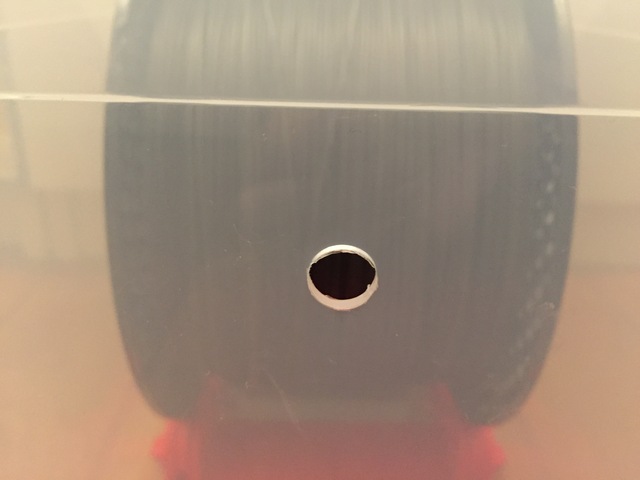

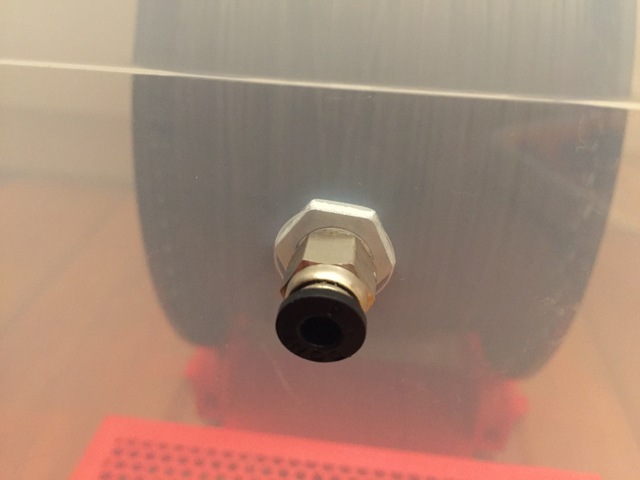

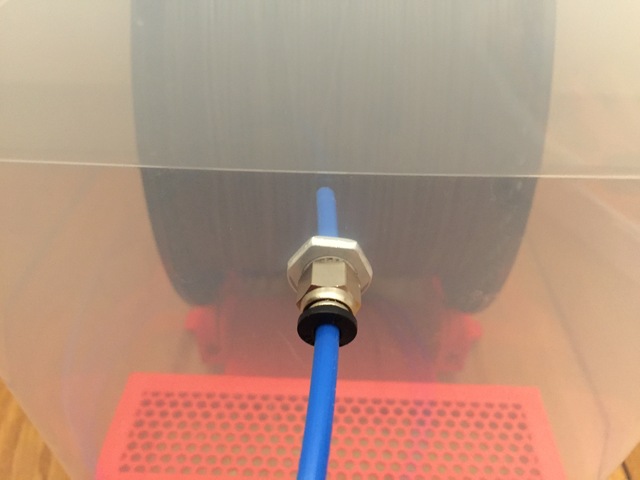

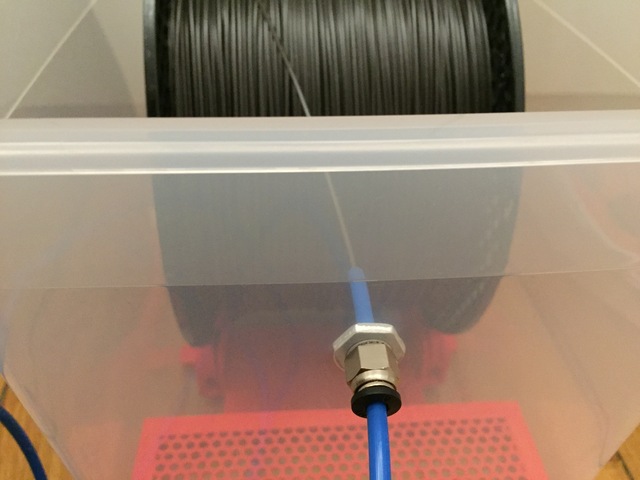

OK, so now the spools can roll inside the box, but how to get the filament out of the box? Quite simply by drilling a hole, and using pneumatic connectors and PTFE tubes, just like the ones used in 3D printers.