DIY soldering fumes extractor

When soldering on electronic boards, fumes are produced and they are not quite healthy. Since I’m starting to do some electronic projects and that I have a 3D printer, I thought about making myself a fumes extractor (also I remembered watching Heliox making one), that could be a good exercise to start learning 3D modeling software.

So I need to design a box that will contain:

an active charcoal filter: there are plenty of carbon filter sheets available but most of the time they don’t provide how much carbon they contain (usually not much). So I decided to make my own, raw active charcoal being quite cheap (~15 €/kg).

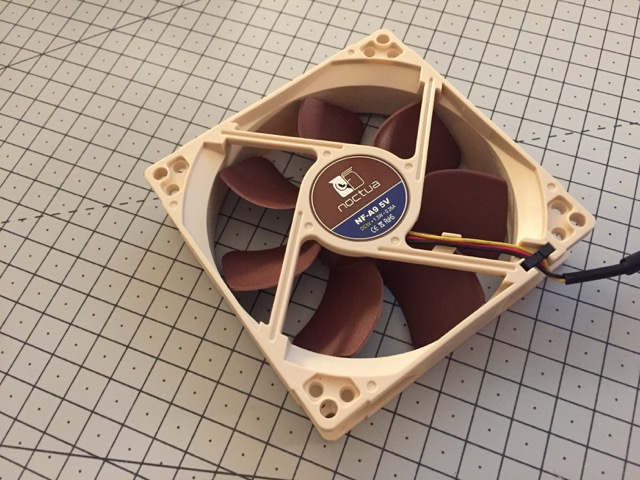

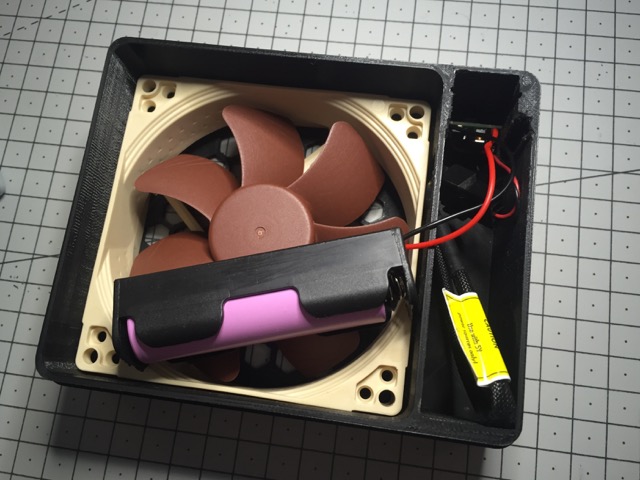

a fan: my 3D printer printing surface being quite small, from the most common fan sizes, I can go up to a 92 mm fan. I also want a fan that is quiet, working on 5 V and with a good enough static pressure to push/pull the air through the active charcoal filter. I quite like the fans from Noctua (except for their color) so I took the NF-A9 5V:

- 92 × 92 × 25 mm

- 22.8 dB

- 78.9 m³/h

- 2.28 mmH₂O

- 5V (USB adapter included)

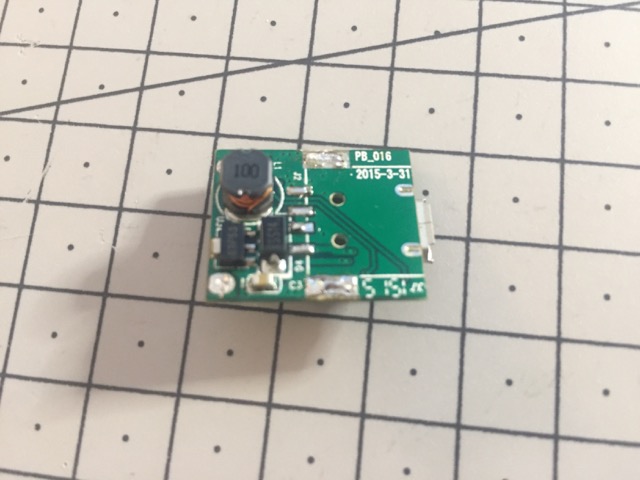

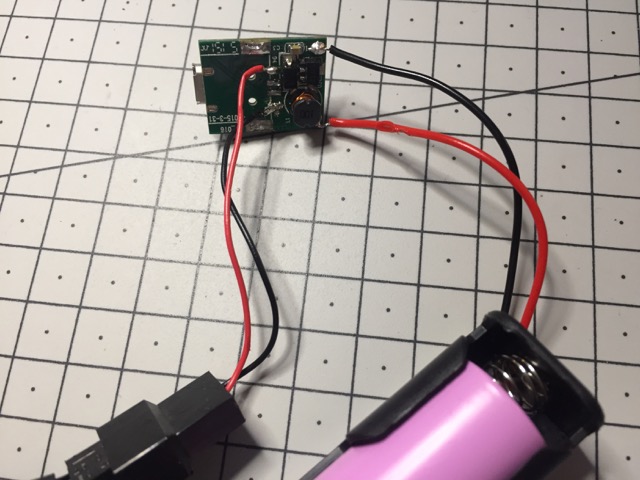

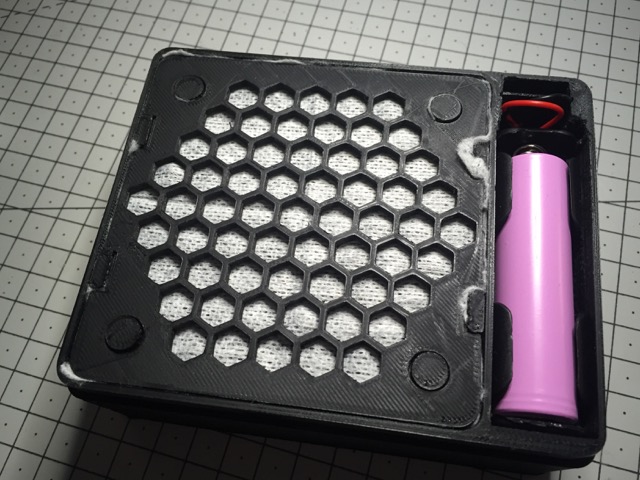

a battery with its electronic board. I happen to have an old power bank that’s composed of a 18650 battery cell and a USB charging circuit:

Active charcoal filter

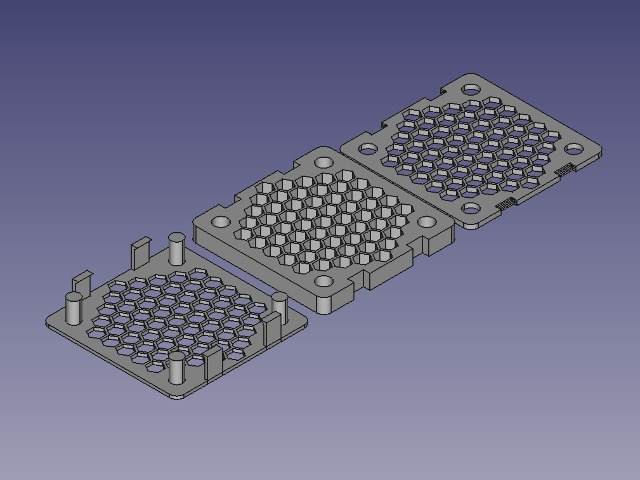

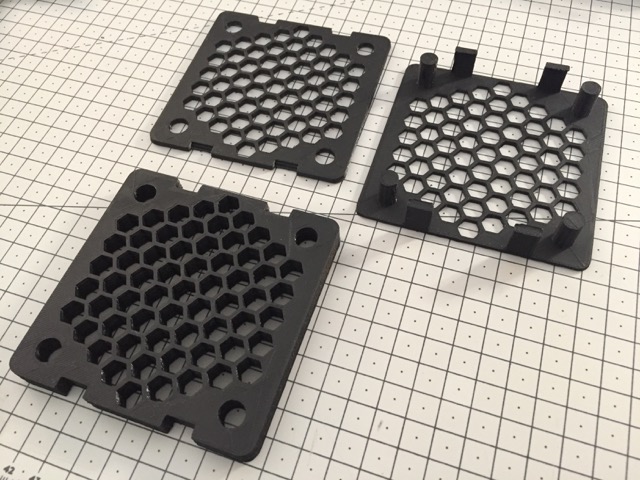

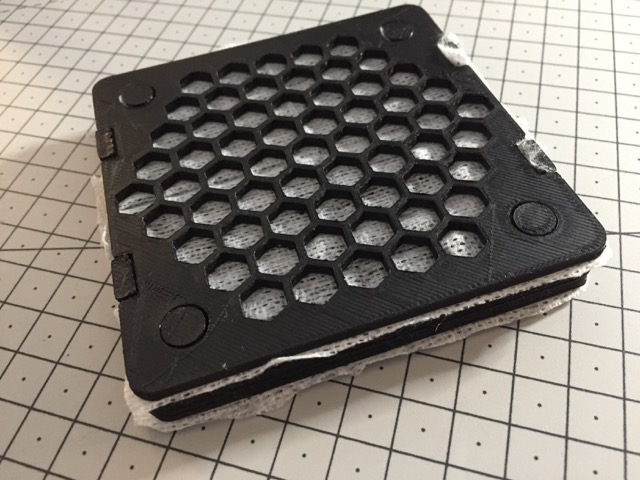

The idea is to hold small charcoal pellets between 2 layers of some kind of thin cloth with low air resistance but able prevent coal dust from falling out of the fumes extractor. I designed a frame to hold all that.

Battery

- take the battery apart

- unsolder the USB A port (only need the micro USB port for charging)

- solder the fan’s 5 V adapter

- got a 18650 battery holder, so solder that too

Assembly

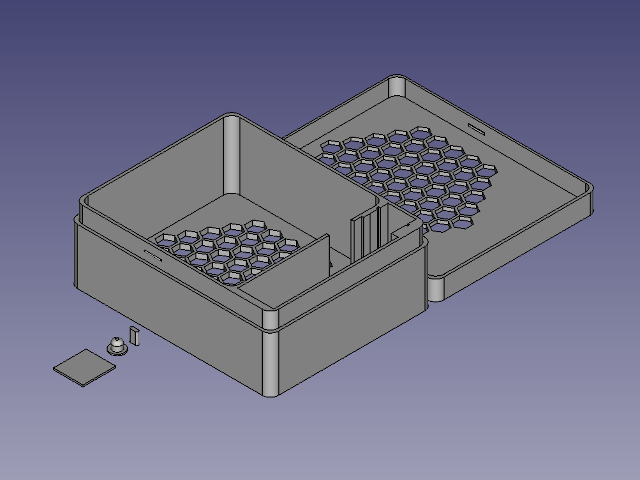

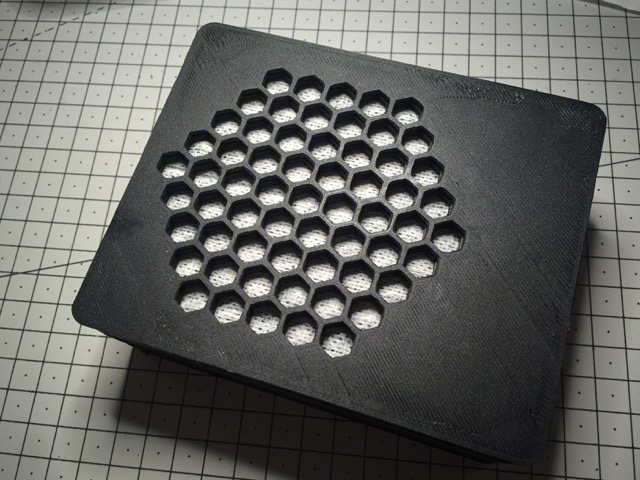

I used FreeCAD to design the case:

- one emplacement for the fan and charcoal filter

- one emplacement with notches to slide the charging circuit in (I did a small plate to insert behind it to keep it in place), there are 3 holes in the box:

- one for the micro USB charging port

- one for the on/off button

- one for the 2 LEDs showing the circuit status (powered on and/or charging), one small piece has to be printed with transparent filament to be used as a light pipe and inserted in that hole

- one emplacement for the cables and the battery and battery holder

After printing it I realized that some improvements were required, I did some but not all of them. Anyway, here is the FreeCAD fumes extractor 3D model.

Test

I did different tests and as I suspected, it’s far more efficient to have the fan push the air through the charcoal filter than having it pull the air from it.